Vibration Analysis

At VibeTekk we endeavor to take the mystery out of vibration analysis. Our approach is to report & discuss our findings clearly with our customers. We do our best to remove ambiguity in reporting of developing failures thru experience and education.

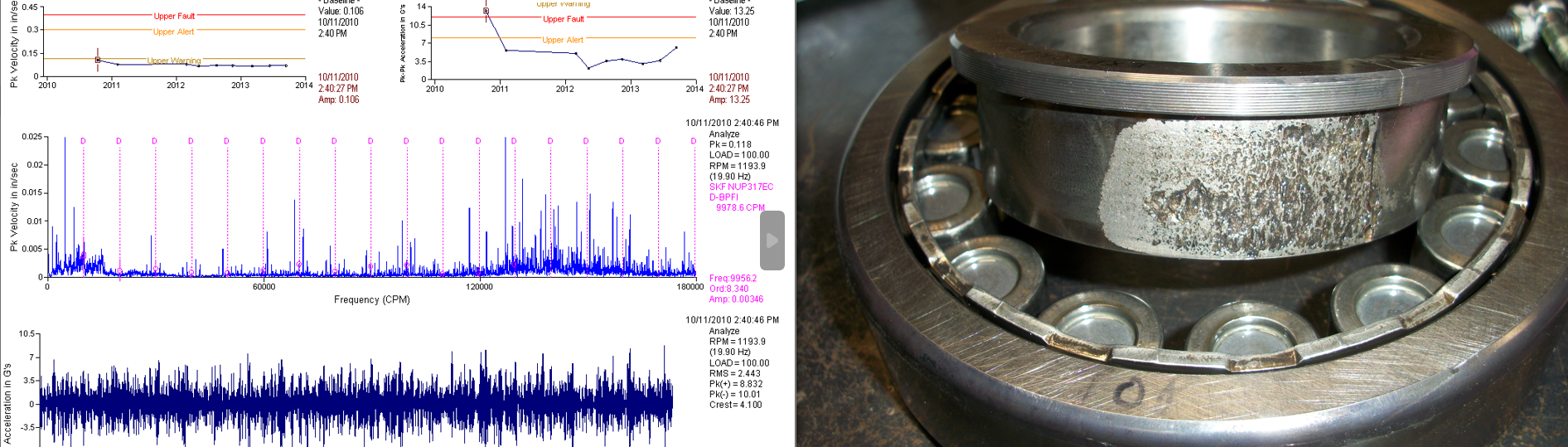

All rotating equipment vibrates. The task is knowing when the level of vibration becomes destructive and what is causing the excessive vibration. Some vibration is very apparent. It can be seen or heard. Excessive vibration that can’t be seen or heard may go unnoticed far too long resulting in catastrophic failure. VibeTekk’s Expert Analysis combines exhaustive in-the-field experience, state of the art technologies and breadth of knowledge to determine if the vibrational pattern we observe is good, bad or potentially catastrophic.

A majority of common issues that we detect with vibration analysis:

Foundation degradation

Mass Imbalance

Misalignment

Belted application faults

Structural looseness

Bearing faults

Gearbox faults

Bent or bowed shaft

Hydraulic and Aerodynamic forces

Flow Turbulence

Cavitation

Blade & Vane pass

Electromechanical Forces

Stator defects

Rotor defects

DC Motor and drive defects

Eddy Currents

Electrical Discharge Machining (EDM) in bearings

Resonance common on variable speed applications

In addition to the common failures we see, there are many problems we encounter that are uncommon and some even elusive. Complicated problems may require advanced techniques to uncover the cause of these uncommon issues. At VibeTekk we have encountered and documented numerous issues that have needed specialized attention and solutions. Cases where the offending vibration may be too costly to eliminate but can be mitigated thru isolation or vibration control.

Uncommon problems we see:

Resonance

Structural

Critical Speeds

Nuisance related vibration upsetting work environments

Large scale vibration affecting plant operations or buildings

Excessive vibration affecting piping systems

Unwanted vibration adversely affecting computers, electronics, manufacturing equipment, nanotechnology, lab equipment, and medical research equipment

Transient or intermittent vibration

Re-occurring failures